Universal vehicle inspection

A technician performs an engine diagnosis.

What is universal vehicle inspection for and will it work? We are told that Kenya’s inspection system for commercial vehicles will soon be extended to include private cars. How and why is this being done? Will it achieve the desired effect?

Anon.

Short answer: There are a great many ways to improve the roadworthiness of private vehicles. Universal annual inspection is one of them, but simple logic and wide experience of existing systems in Kenya and elsewhere suggests it is unlikely to have a positive outcome unless it is preceded by more urgent, more important and more effective measures.

The authorities might have good reason for what they are planning to do and how. They may have reams of data to justify and astutely design the new strategy.

But so far the answers to all three of your questions can only be guesses, because specific details of the process and purpose of the announced policy are not yet generally known.

Here are some thoughts to help you make a more informed guess:

Longer answer: Vehicle inspection is only a physical check for defects. It is an optional tool, a peripheral extra method to support the very, very much wider core objective of overall “Roadworthiness” which is so crucial to reliable and cost-efficient road transport, environmental protection, and road-user safety.

More important things to consider:

The prime determinants for achieving these outcomes are, in an order of priority:

Driver competence: Rigor of training and testing, knowledge, experience, diligence.

Road conditions: Surfaces, design, maintenance, marking and traffic flows.

Workshop skills: Training, equipment, accountable discipline.

Parts: Quality, availability and affordability.

Condition of base vehicle stock: Quality, age/mileage, specification, pre-registration standards.

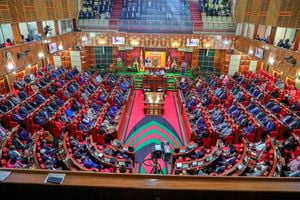

Motoring culture: Maintenance ethic, education, compliance with existing roadworthiness rules already approved by the public through their representatives in Parliament.

Balance of accountability: Mutual respect for rights, responsibilities and standards between road users, suppliers, regulators, enforcers, policy and administration, and the compliance and social peer pressure that emerges when that balance is well achieved.

Vehicle Inspection is not even on the list unless and until all those core measures have been optimised to the highest possible and reasonable standard. I am not aware of any example where inspection without those ingredients has delivered more efficient transport, environmental protection or safety.

A mechanic does motor vehicle wheel balancing.

First things first

Countries with the best roadworthiness performance did not achieve that status through vehicle inspection. They initiated inspection when they had already achieved high standards on all the core elements.

Generally, they have well taught and rigorously tested drivers, with cars of low average age, regularly maintained in good condition by competent mechanics with access to quality parts which they can well afford, and excellent roads. In those circumstances, there is a very good chance that if a vehicle passes inspection today it will remain roadworthy for the following 12 months. Indeed, that is their benchmark for a pass.

In our context and conditions, even a car which legitimately passes inspection today has a high chance of developing defects in less than 12 months, even within a week…or an hour. One of the most emphatic endorsements of the inadequacy of an annual check has already come from Kenya’s leading transport and safety authority. If I remember correctly, when laws on used spare parts were being reviewed, they continued to be allowed as long as the parts were guaranteed by the seller. In more than a few cases the guarantee period was…one day!

Self-checking

Cars do not need a check once a year. They need to be cursorily checked every day (even all the time as they are driven along), a bit more closely under the bonnet at every refueling stop (every week?) and thoroughly at a full service every few months. And in most cases they are! By their owners would welcome annual inspection if they believed it would help them achieve those objectives. They don’t.

So what will the new inspection system do to convince owners that it is there to guide and help them, not just to charge, catch and punish them?

Again, memory permitting, the NTSA justified its used parts decision on the basis that 95 per cent of accidents are not (repeat not) caused by defective parts. Even in the five per cent in which defective parts have been identified as an ingredient, it is probably fair to estimate that they were not wholly and solely to blame for cause or consequence in every instance.

Further, there is a 365:1 probability that most of those accident-causing defects would have arisen “between” checks even if there was a universal inspection system, so the number of accidents inspection is likely to prevent is a tiny proportion of five per cent.

Mission Impossible

Another common denominator of all universal inspection systems elsewhere is that they are all run by the private sector. Here’s why:

To inspect every vehicle in Kenya once a year would need more than 10,000 inspections per working day (!) even assuming perfect synchronicity of bookings. Add more for re-testing of failures.

Any meaningful inspection would require a team of two already experienced mechanics with additional specialist training. If perfectly efficient, each team could check a maximum of 10 vehicles per day (in reality about half that, or not do the job properly…in which case, what is the point?)

So the system would need at least 3,000 high-grade mechanics and more than 1,000 well-tooled inspection pits, all of which would need adjacent test drive areas and a clerical office (with how many management/admin/support staff for the paperwork?). Factor in contingencies for sickness, absenteeism, poor timekeeping, tea breaks, equipment failures, power cuts, ins and outs, booking flow consistency etc.

The cost to motorists of getting to inspection centres would be equally eye-watering. How many centres would there have to be to ensure there was at least one within, say, 20 kilometres or even 100kms of any vehicle?

Expanding a parastatal inspection system with effective proficiency and sufficient capacity would be an investment of billions with high ongoing running and manpower costs. If vehicle owners were charged to cover that cost, every cent more they paid for inspection (and for getting to a centre) would be a cent less they had available to look after their cars properly in the first place.

The system would need to demonstrably deliver more reliable, economic and safe transport. How would it do that if, at the very best, it only did what most motorists were already doing when they took their vehicle for routine service?

A technician performs a motor vehicle engine diagnosis.

Whatever the truth of the matter, is it unreasonable that many motorists believe that inspection is not so much a help and a guide, but more a form of coercive control or fee collection?

In that context, motorists inevitably consider what else all that resource could be spent on, by the State or private motorists, towards the essential and only legitimate objectives of reliable and cost-effective transport, environmental protection, and the safety of road users. For example, if all vehicles are going electric, might it be more useful to spend the money on solar powered recharging hubs?

Better ways to get there

The private sector already has all the necessary inspection facilities and all the necessary manpower, and motorists already visit them several times a year for regular service. “Inspecting” cars when and while and where they do that would require zero additional investment, zero additional cost for motorists to get there, and chump change to have the vehicle item-checked while it is already undergoing maintenance.

Surely, every motorist who takes his car for service expects – and often specifically asks – the mechanics to be alert for and check for anything else that needs attention. The majority would want to know if something was wrong and would already be in exactly the right place to have it put right. The convenience of that would encourage them to take the remedial action immediately.

This also reduces pressure for corruption. A garage mechanic has more to gain from fixing a fault than by pretending it doesn’t exist.

To do any better than that at spotting defects, official inspectors would have to be the cream of the cream of experienced mechanical experts…yet never actually fix a car. For a public sector system of universal inspection, several thousand of those would have to be found…and taken out of the private sector where currently they do fix cars. From motorists’ point of view that only detracts from the best skills resource which they constantly seek at service workshops.

An official inspectorate with no mandate to repair increases the pressure for corruption; rent-a-blind-eye is the only profit margin available.

Carrots, not sticks

Elsewhere in the world where regular inspection systems have been established and are working well, they were the last - not the first - step. And they followed decades of preparatory investment and work on all the other elements of safety, running economy and transport efficiency.

Before formal inspection (the “MoT”) was made universal in the UK, all the other aspects of their motoring conditions had already addressed and much enhanced as a higher priority and became unrecognisably different from ours. And when the time was right for inspection it was (and is) conducted by the private sector. The system was introduced in progressive phases amid a massive and supportive public education campaign, and motorists took their cars to people they already knew and regularly used…not to a stranger in the role of a kali policeman. Spot the difference?

Their Government inspectors don’t try to check tens of millions of cars. They inspect a few thousand garages, licence them, and monitor their performance.

Surely there can be no doubt where and when inspection can be most rationally conducted.

The logical deduction from such empirical evidence is that annual vehicle inspection does not, on its own, prevent, diagnose, remedy or reduce vehicle defects. It never has, does not and never will lead or anchor roadworthiness. Anywhere. In Kenya’s motoring conditions, maintaining a vehicle in roadworthy condition is difficult. Annual inspection would add to that burden, and do nothing to ease or ensure it.

So what formal “check” system might?

An official writes down motor vehicle inspection report. The private sector already has all the necessary inspection facilities and manpower.

A simple PVVC system

Here are some quick notes on how a Private Voluntary Vehicle Check system might work. It could be voluntary and basic until it gained acceptance and proved its viability and value:

1. Limit State inspection of private vehicles to pre-registration only. And make it ferocious – to the extent that a pass justifies demand for a meaningful guarantee (of more than one day).

2. Introduce annual inspection of workshops (with grading and licensing).

3. Require licensed workshops to offer a “check” of 50 items at every service (cars: average three times per vehicle per year).

4. Two mechanics with additional specific training in diagnostics and a systematic work pattern could do the job thoroughly in about 20 minutes.

5. Where a check shows no defects, or where defects are immediately fixed, the workshop issues a “VVC Roadworthiness” certificate.

6. Insurance companies could require a recent check certificate from a licensed workshop as a condition of insurance or renewal (imposing a discount/surcharge formula for compliance/default).

7. This offer would be appealing to the majority of motorists – no extra journey, no extra cost, and real assurance of a vehicle’s condition. Guide and help. Not catch and punish.

8. That means extra business for licensed workshops – an incentive to invest in equipment, skills and quality diligence. Nationwide.

9. Much reduced leverage for corruption at the check/fix point.

10. “Voluntary” status would not generate any resistance, and would attract interest in potential benefit.

11. Reduce or remove duty/tax on new OE parts that are safety critical.

12. Tax revenue losses would be much lower than consequential national costs of operating defective vehicles.

13. No government investment required in the check system.

14. State inspectorate not abolished, just reassigned

15. Introduction of PVVC could be phased until tested, accepted, liked.

16. Build public, commercial and policy confidence and familiarity.

17. Combine with public education campaign.

18. Initially simple workshop licensing criteria, getting stricter with business-winning incentive.

19. Progressively refine the 50-item checklist, increasingly focused on more thorough check of the most safety-critical elements.

20. All vehicles get checked, just as thoroughly as inspection, much more frequently, with enabling incentives instead of unilateral threats.

21.No additional non-productive time or cost.

22. A possibility of significantly improved roadworthiness, built into rather than disrupting motorists’ regular lives.

Robust data essentials

If the public (stakeholders) are to offer an informed opinion on the universal inspection plan, they need an open access website which describes, explains and justifies the design and introduction of the system…and its cost.

Next week: 15 essential preliminary steps.

Do you have a Motoring question? Email [email protected]