They leave for the mines, never to return

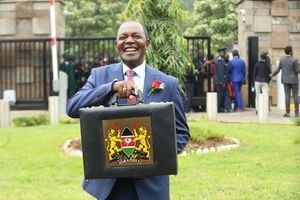

Miners ascending from the Ku-Mullo mine pit in Osiri hammer and chisel in hand. They have no protective gear save for a torch fastened to their heads. No helmet. No boots. PHOTO| PAULINE KAIRU

What you need to know:

- These perilous gold mines have snatched not just one or two lives, but many more villagers here would rather not put a number to.

- Ask the miners however, and they will tell you that this is just a hazard that comes with the job.

At a small village in Arombe, Migori, a family is mourning their departed son. Duncan Odhiambo, 29, passed away on November 29 this year in a pit where he had been mining gold. Cause of death? Carbon monoxide poisoning. He inhaled the deadly fumes, found in poorly ventilated or confined spaces, such as mines.

His wife, Rachel Awino, says that on that day, Odhiambo headed to the mines before 6am, earlier than usual. Around midday, news started to filter through that there had been an accident at Ka-Rondo mines, where Odhiambo worked,

“I ran there but did not see him. Those that he worked with were being pulled from the pit barely unconscious and rushed to hospital. He was the last to be pulled out. He was dead,” recollected an inconsolable Awino when we visited the family last week. Her husband had been mining for only a couple of months, and they had been married for just a year.

With her husband gone forever, it is now up to Awino to take care of their baby, who will never know her father.

Every evening, friends, especially the young men who worked with Odhiambo around the neighbouring mines that litter these parts of Migori County, gather at his parents’ compound to console the family.

When the day breaks however, they return to the same mining fields that robbed them of their friend and many others before him.

It is a day-long process that starts with pumping of water out of the pits. The petrol-powered generators used to pump the water above ground have to be first lowered into the deep excavations.

“Without adequate ventilation systems in place, the fumes released within the pits by these generators can easily kill - it is these carbon monoxide fumes that caused Odhiambo’s death,” says Bismarck Onyando, the chairman of Micodepro — an association for miners in Masara area, where most mines are located. It is about three kilometres from Odhiambo’s home.

Just three weeks ago, another miner died here after he drowned in yet another mine. Area chief, Paul Tumbo, says an old poorly supported stope collapsed, causing the miner to fall. He drowned in a pool of water.

Work here involves mining of hard rock in underground workings, mostly in old and abandoned mines from the colonial era. The mines are accessed mainly by precarious-looking adits. Once in, the miners shift sack-loads of rock of ore to the surface.

For the miners, it is a life fraught with risks. From accessing the gold-rich ore in abysses as deep as 190 feet to falling boulders when burrowing, and suffocating dust from the blasting of ore, almost every stage presents with serious health threats.

DEATHTRAPS

The mines tell a story of a toilsome and perilous undertaking that has snatched many lives, respiratory problems caused by inhalation of poisonous fumes and the occasional collapse of a tunnels.

Disturbingly, the miners view this as just hazards that come with the job.

“This is what nature has gifted us. While others have fertile farming fields with cash crops, we have a place considered a hardship area that is rich with gold,” says Onyando, the miners’ chairperson.

The economy here is highly dependent on the bustling mining activities. Fields remain bare. Rarely does one spot any tilled land. In fact, the sound of a ball-mill crushers at work is the dominant sound in almost all homesteads here.

On the 13 kilometre rough stretch of road from Masara township leading to the Osiri mines—one of the most productive—neat brick houses are coming up everywhere. They are not palatial, but they are dignified, telling the story of a flourishing economy in rural parts of Migori.

Gold mining has become a major contributor to local income and a pillar for poverty reduction.

The kind of mining going on here is what the law recognises as artisanal gold mining; artisanal because it is characterised by bare minimum mechanisation.

Onyando explains that the miners generally do not conduct exploration. All is on a trial and error basis. Miners rely mostly on their instincts and experience gathered over the years by operating in a particular geological setting to identify mineral bearing rocks.

Joseph Owino, a supervisor in one of the mines further explains: “We have well established veins which we follow.”

The industry has a serious impact on people’s lives; both good and bad. Artisanal underground mining is inundated with unsafe conditions and practices, yet seven out of the eight sub-counties in the county which has a population of about one million people, is dependent almost entirely on artisanal gold mining.

DN2 spent time at Osiri mines, a Trust land managed by the county government, where most of the mining in the county takes place.

DAY’S PAY

We catch up with Anthony Onyango at a gold dealer’s kiosk selling his day’s produce—a tiny rough pea-sized stone of gold.

Nickson Hezron, an excitable young man who runs the makeshift shop made using iron sheets, weighs the gold. It is only 0.97 grams, but Onyango considers it a good day. He gets his Sh3,100 and disappears into the mines, where other miners are heavily engrossed in processing their ore.

Mining is a lucrative industry that is burgeoning in many parts of Western Kenya, however, it is a game of chance. Sometimes the backbreaking work pays off. Other times, it does not.

Onyango admits that on bad days, he goes home empty handed. “Not because I haven’t been into the pit digging, but because the ore was bad. But then there are days when I’ll get up to two grams of gold or more”

COST OF GOLD

Currently, a gram of gold here is selling at between Sh3,000 and Sh3,500.

But this is no secure venture, it is a gamble, a dangerous job that is characterised by cripplingly dreadful working conditions. The miners do not know the amount of refined gold they will get from the ore in their sack on any given day.

Just like Onyango, on this day most of the miners have been in the pits since 7am. Other than the torches fastened to their heads by an elastic bridle, hammer and chisel in hand, they have nothing to protect them from what awaits them there - no helmet, some even have no boots. They descend into the pits one by one. They will be there for at least eight hours, only taking a short break to eat some bread and milk or drink water from deep in the ground.

They are wary of wasting any time. Using their rudimentary technics to extract as much ore as they can; the broken rock is transported out of the pits in sacks using a manual-return-pulley for ‘refining’.

At the mouth of the pit, the mine owners and workers share their ore at a ratio of 2:1, sometimes 3:1 when the gold bearing rock is too rich with gold.

Meanwhile, outside the makeshift structures constructed to protect the mine pits of the close to 30 active mines from intruders, groups of women wait by the doors of especially the most productive pits. They push and shove, waiting to pounce on any material that may be regarded as waste, or that which may drop from a sack of ore coming from the pits. Anything really. Even a sack that has been abandoned by the miners is good enough. They pick and wash it in basins that line the entrances, hoping to spot any promising rock.

The mine workers leaving the pits with their heavy sacks of rock head out to either sell their find to middlemen, or process it themselves.

Out in the open across the mining fields, more men and women sit hunkered over mounds of rock, crushing it away.

The ore, which is basically rock, is first manually crushed into smaller grits with metal mortars and rock pestles before being taken for grinding by elementary mechanical ball-mill crushers, into a fine cement-like powder. Still, work here is done without any sort of protective gear, not even masks, in spite of the dangerous airborne dust.

In this powder are the gold particles, so fine, they cannot be seen by the naked eye.

WOMEN’S WORK

It is this powder that is taken for sluicing; a process in which the powder is sprayed with jets of water over a slanting wooden channel lined with gunny bags used to catch the gold particles from the muddy solution.

The water washes down fine gravel containing gold so that it can be directed into sluice boxes and recovered using gravity separation (where the heavy gold is trapped at the bottom and the lighter sand is washed away).

It is 3pm and Anastasia Anyango has just finished sluicing some gold-rich powder. She has been hired to do the work by one of the miners. The women often do the work for a fee of about Sh200-Sh300.

Here too, no safety gear is worn during the process.

And so with her bare hands, Anyango washes out the bags in a large trough of water.

Eventually, the gold rich mud sinks to the bottom. All the sacks of rock emerging from the pits are subjected to this doggedly slow process, markedly the women’s job.

***

WOMEN AT RISK OF MERCURY POISONING

Mercury is the elixir of miners in Migori mines. They all use mercury amalgamation; a technique heavily relied upon for gold recovery in small scale mining. The miners say that mercury allows them to recover three times the amount of gold they would without it. They get the mercury from the same Indians who buy their gold.

Gold particles effortlessly stick onto mercury, isolating worthless dirt from the prized metal. This process is called amalgamation. The gold is dissolved into the mercury to form an amalgam.

While the dark underground tunnels are cloaked with danger for the male workers, women processing the ore outside the pits are exposed to an even greater adversary-mercury.

Anyango says they use about two bottle tops of mercury for a basin of the sluice-water solution. “That is what you stir to form your amalgamation,” she explains, as she swishes and decants the suspension, over and over, leaving the gold concentrate (if any) at the bottom of the basin. It is an arduous task that requires a lot of patience.

“You have to go on until you’re left with the gold solution which normally sinks at the bottom of the container. Then you add the mercury. And the swirling continues until the drop of mercury has accumulated enough gold to form a tiny silver-coloured gold globule of amalgam,” she adds.

THE DANGERS

In the end, the amalgam is burnt on a bowl or spoon on a fire. The mercury evaporates, leaving behind the pebble of gold. “We use mercury but no one has been made aware of the dangers of using it,” says Anyango.

According to Dr Tom Menge, the chief toxicologist at Kenyatta National Hospital, this is one of the most hazardous stages because the fumes released from the burning process escape into the air and are inhaled by the workers. “This mercury is easily absorbed into the body through inhalation and the skin during physical contact,” he says.

He says symptoms of mercury poisoning are mainly due to chronic exposure of small quantities over time. They include loss of sensation, numbness, muscle weakness and incoordination. “Chronic exposure over time leads to its accumulation in the body, which affects the central nervous system,” says Dr Menge.

“If it gets to the lungs, it is very dangerous because it gets into the blood stream and affects many enzyme systems in the body, where it displaces zinc, selenium ferrous and calcium,” he adds. Eventually, the exposure to high concentrations may lead to respiratory distress and injury to the kidney, liver and lungs and other illnesses. Most of the ailments associated with mercury toxicity are cumulative and only become evident after long periods of exposure. Yet treatment is very expensive or even unavailable. “First of all, it is difficult to determine mercury levels in the body. Then treatment which has been a contentious subject is through chelation therapy, whose effectiveness is controversial,” he says.

Studies have also associated mercury poisoning on pregnant mothers to autism of their new borns.

“People don’t know the consequences of using mercury,” says Dan Odida, the secretary-general of Micodepro -an organisation that has undertaken a number of initiatives to encourage responsible artisanal mining operations. Asked whether they realise the harm they expose themselves and the environment to by using mercury, many look unruffled. Some of them have heard about the risks but they say they can’t do without this magic portion. “If it weren’t for the mercury, we would not be here. This work is not easy. It would not make sense without the mercury,” says Ambrose Okeya.

Caroline Atieno is seven months pregnant. We find her collecting and working with gold tailings that are heavily laden with mercury oblivious of the dangers this poses to her unborn baby. Asked whether she understands the environment she is working in could be perilous to her unborn child, she says, “I don’t know much about that mercury.”

Alarming too is the fact that the Osiri mines sit on the banks of the Kuja River, a tributary that drains into Migori River, which feeds Lake Victoria. This means that the discharged waste may be flowing into the lake- about 20 kilometres away- introducing mercury traces into the aquatic environment.

Inadequate monitoring of the mining operations and lack of regulatory enforcement have been blamed for the environmental and safety hazards. Migori County Inspector of Mines Raymond Odanga acknowledges that little to no research has been conducted to ascertain and address issues related to small scale underground mining in the region and other areas in Western Kenya.

Currently, Kenya has no legal restriction on the use of mercury.

But Odanga says he can’t fully underscore how dangerous mercury is to the environment. “There is not yet capacity to educate the miners because until the passing of the recent mining Act, these miners were not recognised. They were considered illegal miners. But now that the law recognises them, once they are licensed and their activities are regulated, their working conditions will be improved,” he says.

He adds that when the structures are put in place and there is government supervision, the miners will be helped to acquire safe and advanced mining equipment and be educated on the dangers of mercury use, thus minimising hazards.

Odanga adds that for the same reasons, the government does not have statistics of the miners who have died in the mines. Besides, he adds, “miners invariably do not report accidents because of fear of drawing attention to themselves since they know the government will close down the mines.”