Silk cocoon produced at the China-Africa Modern Silk Industrial Park in Eldoret.

| PoolSeeds of Gold

Premium

Chinese weave dream to make Kenya leading silk producer

Since the collapse of cotton farming in Kenya, the local textile industry has been struggling, with plans to revive the sector rolling at a snail’s pace.

The injection of the incentives under the African Growth and Opportunity Act (Agoa) gave it a lifeline, but the industry is still in the woods.

In Eldoret, however, a group of Chinese and Kenyan investors have embarked on a journey that they hope would give the sector the boost it deserves.

The agriprenuers have planted mulberry on two acres, on which they also keep silk worms, in the first steps that would see them run their silk production agribusiness on 50 acres.

“The two acres are a pilot phase as our intention is to establish a China-Africa Modern Silk Industrial Park. We are partnering with the DL Group of Companies, a Kenyan firm,” says Ethan Peng, a senior manager at the industrial park.

They keep the Bombyx mori silkworm which feeds on mulberry leaves to produce high quality silk.

Gold Silkworms.

“The silk we are producing in the pilot phase is at level 5A, a very good quality. We got very positive results. This gave us the confidence to expand,” says Peng.

There are three main grades of silk, categorised as A, B and C. Grade 6A is the highest quality, while 5A is one of the best.

Silk is a natural fibre valued for its strength, softness, durability and lustre. It has a long-trading history across the world. Though several other insects can produce silk, silkworm has been preferred for the production of commercial silk fibres.

At the inaugural China International Import Expo at the Shanghai International Convention Centre On November 5, 2018, President Uhuru Kenyatta met the Chinese investors behind the silk production in Eldoret, Guangdong Silk-Tex Group, which is the parent company of China-Africa Modern Silk Industrial Park.

“This investment will create some 300,000 jobs and initiate cocoon farming covering more than 200,000 acres. Such investments offer mutual benefits: they generate jobs, create a value chain and guarantee favourable returns on investment,” President Kenyatta said at the Expo.

With the President’s endorsement, Peng says that the project has received support from the Ministry of Industrialisation, but they would want more to be done, especially the incorporation of the sericulture industry into the country’s national economic plan and tax incentives.

“In the process of promoting the project, it is necessary to import mulberry and silkworm varieties from China and related production and research materials. We ask the Kenyan government to grant import policy permits and tariffs,” the investor says.

DL Group of Companies chairman David Lang’at asked the government to fast-track pending approvals and licences so that the project can fully be rolled out.

“This is a project that will put Kenya on the global map of silk producers. We request Kenya Plant Health Inspectorate Service to move with speed and support the project that sits well with the Big Four Agenda in terms of job creation and industrialisation,” says Lang’at.

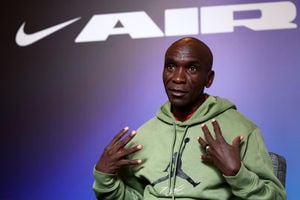

Ethan Peng, a manager at China-Africa Modern Silk Industrial Park, at their 50-acre farm in Eldoret.

In the pilot phase, Peng says that they were able to harvest about 15,000 kilos of mulberry leaves per acre. And then from the harvest per acre, they were able to get about 800 kilos of cocoon, which is made of a thread of raw silk. It means that if the entire project area of 50 acres was put under use, the project would generate about 40,000 kilos of cocoon.

The expansion has, however, been delayed by the Covid-19 pandemic, which saw some of the Chinese experts working on the project return home.

“If not for Covid-19 that has forced us to suspend activities for some time, I think we could have finished the second stage of the 50 acres. Some of our experts went back to China and we are waiting for them to come back so that we pick up from where we left,” he says.

According to Peng, the idea is not to stop at 50 acres but to adopt an out-grower model by contracting farmers across the country.

Initially, he says, the contracted farmers will only grow the mulberry on their farms, which will be harvested and sold to the company.

An initial estimate shows that a farmer can earn between Sh250,000 and Sh300,000 per acre of mulberry. The investors say that the farmers they have so far talked to are willing to farm the mulberry.

The ultimate plan is to train the farmers not only to grow mulberry but also rear the silkworms.

“At that point, they will be selling to the company the cocoons instead of the mulberry leaves,” says Peng.

The initial plan is to export the raw silk given that there is no processing plant locally. However, the investor says that with time, they will move to value addition by making the final silk products locally.

“The third stage of our silk industry base construction will be to gradually realise the industrialisation system of modern mulberry sericulture technology in Kenya,” says Peng.

Newton Owino on his silkworm farm in Kisumu County.

The investment in silk farming in Eldoret coincides with the recent award of a licence to Africa Economic Zones Ltd (AEZ) to develop and operate Kenya’s first licenced Special Economic Zone (SEC) in Eldoret town.