Lower energy costs key to making locally made products competitive

Kenya power technician disconnecting illegal electricity connection at Milimani Estate in Nakuru town on March 30, 2021.

What you need to know:

- Part of our problem is that we have inherited very expensive politically motivated thermal plants.

- Kenya Power has been asking counties to sign agreements allowing it to continue with reticulation.

The country faced a major power blackout this week. The spectre of sabotage and vandalism of the power transmission grid is cause for worry, particularly given the effort to reform the sector and bring down the cost of power. Could it be a case of corruption fighting back?

The power composite is not working well for us. Part of our problem is that we have inherited very expensive politically motivated thermal plants. Everyone suspects that is why the power grid is being sabotaged. So, let us unpack the power sector.

In China today, the average small manufacturing business pays about eight shillings per kilowatt hour of electricity. They are probably making chaff cutters, which they sell to farmers in Kenya and in the region. The Kenyan manufacturer of chaff cutters, on the other hand, pays Sh19.30 per kilowatt hour.

That is in part because our energy generation mix includes 33 per cent fossil fuels, which are rather expensive. The penalties involved make it very expensive for the country to get out of these lopsided contracts.

Yet these could be replaced with cheaper renewables such as solar. It now takes an average of 10 years to develop a successful power project in Kenya; years of back and forth, hundreds of meetings and structural delays.

De facto monopoly

All this costs money. This is partly why project developers demand a capacity charge. The other reason is that although power generation has long been liberalised, and the transmission assets are managed separately, there is a de facto monopoly in distribution. This means that once you invest in a plant, you are stuck with that capacity, and only the monopoly distributor can offtake.

The Constitution of Kenya 2010 tried to cure this by making power reticulation a county function. Reticulation is conveying the energy from the distribution transformer to the customer.

As of today, no county has succeeded yet in carrying out this function. Kenya Power has been asking counties to sign agreements allowing it to continue with reticulation. But frequent management changes have stalled this process. The CS would do well to enforce this constitutional provision.

Back to the chaff cutter manufacturer. As I have said before, nowhere are our actions as a state more contradictory to our stated goals than in relation to the manufacture of machines and tools.

From the Export Processing Zones Act to the Special Economic Zones Act, imported machinery is given tax preference over locally manufactured ones. As a result, it is cheaper to import motors, pumps, cutting, folding and bending machines.

To help micro and small businesses mechanise and automate, we must repeal all these laws. But all that will amount to nothing if small businesses cannot access affordable, competitively priced power. While we appreciate the 15 per cent reduction in tariffs, the government must do more.

In Laikipia, we are providing a 40 per cent rebate to manufacturing businesses in order to lower energy costs and make them competitive.

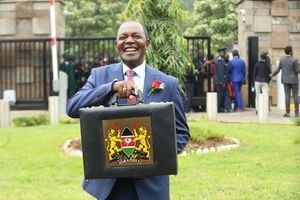

@NdirituMuriithi is the Governor of Laikipia County