Beware what you consume, Kebs mark of quality not guaranteed

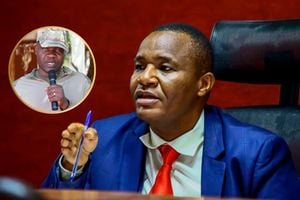

Kebs acting Managing Director Esther Ngari during a past appearence before a parliamentary committee.

Chances that the goods you buy from the supermarket shelves and other outlets are of substandard quality could be high.

This is after Kenya Bureau of Standards (Kebs) confirmed before a parliamentary committee that it does not undertake tests on goods sold locally to ascertain their suitability.

The fears of consuming substandard goods appeared to be confirmed during a session of the Public Accounts Committee (PAC) of the National Assembly on Thursday when Kebs acting Managing Director Ms Esther Ngari said that Kebs relies on the trust of manufacturers to produce goods that are of quality.

Ms Ngari had been summoned by PAC chaired by nominated MP John Mbadi over the government’s expenditure of Sh125.1 million on defective Liquid Petroleum Gas (LPG) cylinders but was dismissed by the committee midstream for providing substandard answers.

The procurement and supply of the defective cylinders was flagged by Auditor-General Nancy Gathungu on the accounts of the State Department for Petroleum in the 2020/21 financial year.

What caught the PAC members by surprise was the admission by Ms Ngari that what Kebs does is the inspection of the premises of manufacturers who meet the criteria provided for in the standards Act before issuing them with Diamond mark of quality.

This means that whatever follows is depended purely on trust from the manufacturer to produce goods that meet the standards.

“Kindly note that it is the responsibility of the person manufacturing a product covered by a Kenya Standard to comply with the requirement of the standards,” Ms Ngari said in response to questions from PAC members on why over 78,000 defective gas cylinders supplied by three companies were released to Kenyans.

Diamond Mark of Quality is a mark that Kebs gives to a manufacturer capable of meeting the quality standards.

Ms Ngari added; “issuance of the standardisation mark attests to an assessed capability to manufacture compliant products but does not transfer the responsibility for ensuring compliance of the specific products being manufactured in the assessed factory to the government or the regulator.”

The admission by the Kebs management saw the committee members propose to amend the law to have Kebs officers who endanger the lives of Kenyans face punitive measures including life sentences.

“I don’t think any more engagement with you is beneficial to this committee. Just admit that Kebs is not doing its job and that it’s asleep on the job. We need to amend the law to provide punitive measures such as life imprisonment for Kebs officials exposing the lives of people,” said Mr Mbadi.

Wajir South MP Mohamed Adow said he was not convinced by Kebs’ responses.

“I am gobs marked. I have always grown to respect Kebs' mark of quality but little did I know they don’t test or inspect the goods coming into the country and even those sold locally. What quality control are you talking about when all is based on trust? How sure are you that what Kenyans consume is of the right standards? Tell this committee,” said Mr Adow.

During the 2017/18 Financial Year, the government through the State Department for Petroleum started the implementation of LPG project that was intended to promote the use of modern cooking fuels among low-income households.

Also read: Food safety on the table at world conference

The project, Mwananchi gas, entailed supply and distribution of 6 kilograms LPG cylinders, grills and burners and National Oil Corporation of Kenya was engaged to distribute the gas cylinders to the households.

Documents presented to Parliament show that Surge Energy Limited imported and supplied 79,998 gas cylinders, Allied East Africa Limited 11,132 cylinders and Accurate Power System limited 15,056 cylinders.

However, the majority of the supplied cylinders were found to have technical defects and were recalled after the Ministry of Petroleum engaged the services of an independent inspector.

An inspection report on the gas cylinders by a technical firm- Bureau Veritas- tabled before PAC, shows that of the cylinders Surge Energy Limited supplied, 27,129 about 33.91 percent passed the tests while 52,869 about 66.09 percent were found to be defective.

All the cylinders supplied by Allied East Africa limited and Accurate Power System limited were defective as they did not meet the standards required.

The defects on the cylinders ranged from valve leakage, visible rust, lack of zinc coating to lack of a stamp indicating the manufacturer and that the suppliers provided incomplete documents for use in document review.

However, Ms Ngari told the committee that Kebs was not involved in the inspection of the cylinders and that she only came to realise of the defective cylinders when PAC summoned her with Mr Mbadi wondering; “how irresponsible can you be?”

This is notwithstanding that the matter was flagged by the Auditor-General in the audited accounts of the State Department for Petroleum for the 2020/21 Financial Year.

Mr Bernard Nguyo, Kebs’ head of Quality Assurance told the committee that the cylinders were not tested because they already bore the Kebs mark of quality.

“We do not test any shipment of goods that arrive at the port of Mombasa as long as they have the Diamond Mark of Quality,” said Mr Nguyo noting that the only thing that happens at the port of entry is the ascertainment that the goods have the diamond mark of quality.

Although Mr Nguyo admitted that Kebs has quality assurance staff at the point of origin and entry for the goods shipped in, the inspection report indicates that there was no proof of external inspection for the cylinders supplied as there were no certificates issued.

Allied East Africa limited did not provide post manufacturing quality control documents.

According to Kebs, for certification to pass the test, the manufacturer must be a registered entity, Kebs must inspect the manufacturing premise to assess the capability of the manufacturing process to meet the requirements of the standards.

The manufacturer is also required to sign a certification contract with Kebs, a systematic guide to quality management activities that the manufacturer implements to ascertain adequate quality assurance.

This is to ensure that quality assurance activities are being carried out in the process satisfactorily and thus giving assurance that the products are continuously meeting the approved specification.

The product upon testing must meet the requirements of the relevant Kenya standard for the product and the manufacturer is required to implement measures agreed in the certification contract throughout the validity period for two years.