When radiators spring a leak…

Most minor radiator faults can be fixed and give reliable long-term service

What you need to know:

- When the radiator cools and the pressure drops, this expelled coolant is drawn back into the radiator by suction, reducing the need for top-ups.

- The system will still run perfectly well if the expansion tank is leaking but you should then check the coolant level more often.

If a car’s engine radiator leaks or gets clogged, is repair a temporary fix or can restoration give it a long new lease of life?

Most minor radiator faults can be fixed and give reliable long-term service – for less than a quarter of the price of a new one.

Radiator repair is low-tech and thus widely available at a modest cost. Pinhole leaks and splits in the radiator tanks can be braze-welded (that’s the system that uses an oxy-acetylene torch and leaves a brassy-coloured repair). Bigger holes caused by corrosion can be similarly patched.

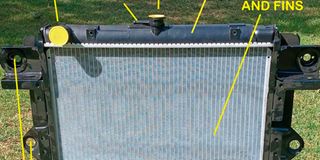

If the thin tubes set in a mesh of cooling fins (the core) are physically damaged, those with leaks can be pinched and soldered shut. If the tanks or tubes are clogged with dirt, they can be scrubbed clean (inside and out).

“Stop-leak” and “Radweld” additives can help stem pinhole or hairline leaks in an on-the-road emergency, but they will not plug bigger holes and are not a permanent repair. The three main enemies of radiators are dirt (which can clog their circulation, promote corrosion and reduce their ability to dissipate heat) corrosion itself (which can weaken the metal skin and lead to leaks and create rust-dirt) and vibration (which can weaken and split sealing joints between the tanks and the core). Physical impact is rare, but the radiator core is fragile.

These hazards are prevented by keeping the coolant clean (adequate flushing and renewal), always using rust-inhibiting additives (which also help lubricate the water pump), and ensuring the mountings (which include rubber pads) are sound.

Ancillaries include water pump, the fanbelts that drive it, the fan itself, the inlet and outlet hoses and their clips, the radiator cap (which needs to have the right pressure-release valve spring), the external expansion tank (follow the thin tube from the neck of the filler cap to find it).

Expansion tank

Radiators have three sections – a header tank (the one with the filler cap), a bottom tank (the one with a drain plug) and a central core made of numerous tubes set in a mesh of cooling fins. There is an inlet hose at the top and an outlet hose at the bottom.

Hot water from the engine block arrives at the top, is cooled by the breeze and a fan as it flows through the core, and passes into and through the bottom tank on its way back to the engine…all in a continuous flow accelerated by the water pump and regulated by the thermostat.

The heat and the pump generate considerable pressure in the system, which helps suppress air bubbles and ensure a continuous flow. If the pressure gets too high, because of excessive heat and inadequate flow, the filler cap has a sprung seal which acts as a pressure release valve.

Even at normal running temperatures, the pressure is enough to expel some steam, which is channelled through a thin tube from the filler neck and captured in the “expansion tank”.

When the radiator cools and the pressure drops, this expelled coolant is drawn back into the radiator by suction, reducing the need for top-ups. The system will still run perfectly well if the expansion tank is leaking (or entirely missing) but you should then check the coolant level more often.

The filler cap needs to have the right spring rating. If it is too weak, it will allow too much steam to escape. If it is too strong, pressure in the radiator will get too high and could rupture internal joints and seals.

Even normal levels of pressure will, of course, accelerate any leakage and the heat of the radiator will quickly dry the site of small leaks when the engine is turned off and the pressure subsides, so there might not be any visible drips.

Temperature gauge

So, check for leaks when the engine is running at normal temperature, and otherwise keep an eye out for rusty-coloured stains as a clue. Well-equipped garages also have pressure testers for radiators.

While radiators need pressure to run optimally, they do still work without it. So if you have plenty of water, one get-you-home remedy for a leak is to take the cap off and drive gently (the leak will be much slower, and the weaker circulation might still cool the engine well enough at low revs).

You should stop and refill if the temperature gauge goes above normal, but this tedious process could get you home or to a garage and is better than sitting on the side of the road waiting for a tow.

If there are numerous holes in the core, the tubes are probably too fragile to repair. If the radiator frame and tanks are sound, it may be possible, though not always sensible, to fit a new core (en bloc) rather than replace the whole radiator.

Top-quality radiators used to be made of brass or a similar copper alloy because it does not rust and is an extremely efficient conductor of heat. Increasingly, modern radiators have a steel frame, top and bottom tanks made of plastic, and a core of aluminium.

The two types are interchangeable without adjustment or modification. Both can give lifelong service; both can use the same glycol additives in their coolant.