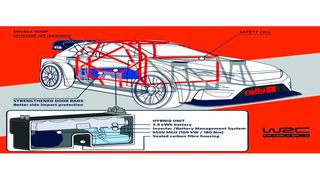

An image of the new hybrid World Rally Championship cars that will be launched in 2022. The technology was approved by the World Motor Sport Council on June 14, 2019.

| Peter Njenga I Nation Media GroupMotorsport

Premium

Under pressure to go green, WRC launch hybrid technology for 2022

What you need to know:

- On June 14, 2019, the World Motor Sport Council approved the introduction of a new generation of R1 Hybrid Vehicles next season

- Peter Njenga looks at the paradigm shift to produce a car powered by clean electricity and a traditional internal combustion engine, a new technology in motor rallying

- The FIA is preparing hosts of the 2022 WRC to handle the new Hybrid Vehicle, code-named HV

Exit the old, welcome to the Hybrid era, and the future. Engineers have continued to perfect safety features, especially on the roll cage, since 1982 when the FIA introduced the Group ‘B’ cars in the World Rally Championship (WRC).

And as the Group ‘B’ cars were banned from 1987, safety continued being part of development.

Rallying and the WRC are, yet again, on trial and under pressure to join the rest of the world by going green to save planet earth.

Engineers took a paradigm shift to produce a car powered by clean electricity and a traditional internal combustion engine, a new technology in rallying but in use in Formula One and Cross Country races ahead of the era of the full-electric car of the future.

However, unlike in F1 and Cross Country where cars are raced in evenly defined circuits, the 2022 World Rally Car 1 (R1) car will operate on open roads ranging from dirt, gravel to the tarmac where the road surface is prone to change from the elements of weather and use.

On June 14, 2019, the World Motor Sport Council (WMSC), approved the introduction of a new generation of R1 Hybrid Vehicle (HV) rally car in 2022, starting with Monte Carlo on January 25 with a five-year homologation cycle.

Key visual elements

Manufacturers will be allowed to use a production body shell or a prototype tubular structure to current WRC size guidelines, while the FIA set to define carry-over elements from production vehicles for key visual elements.

The main innovation was the introduction of a supplementary hybrid system, to be comprised of common components and software for the first three years, with the potential for more technical freedom in 2024, the federation then said.

While accidents in the WRC have been spread far apart, dangers loom in every rally and now, safety marshals and medical personnel have become a cog of the integral wheel that drives the WRC, a 13 round series that attracts close to 900 million television viewers.

The FIA is preparing hosts of the 2022 WRC to prepare a scenario of handling the new Hybrid Vehicle — code-named HV — alongside the traditional internal combustion driven cars.

This requires a set of two experts, each working independently, thus the essence of Kenyans in the e-Safety Extrication and Technical Rescue seminar at the Holmatro factory in Raamsdonsksveer, The Netherlands, last month.

It was a crash programme where ordinary cars and newly-designed HV roll cages were used for practical purposes after the FIA failed to secure an HV R1 car for realistic simulation. The main targets for the improvement of the new structure design included the A-pillar (the pillars on both sides of the windscreen) and the side impacts.

What is an HV R1 car?

All HV cars feature a 1.6-litre direct-injection turbocharged four-cylinder engine mated to an electric motor that adds 100 kW (134 hp) and 132 lb-ft (180 Nm) of torque to the existing 380bhp turbocharged engine.

Vehicles will also be equipped with a 3.9 kWh (750 volts) battery pack which, like the electric motor, is protected by a sealed carbon fiber housing near the rear axle, said the FIA in a statement.

The battery was a subject of discussion at Holmatro, especially its potential dangers to drivers and rescue teams in case of an accident. It is supplied by an Austrian company, Kreisel Electric, and has 750 V, with the inverter control unit sealed in a carbon fibre housing to resist possible forces and impacts in the event of an accident.

External power supply

The FIA said the electric system recuperates energy normally lost and stores it in the battery. If necessary, the battery can also be recharged by an external power supply (plug-in hybrid) during service breaks.

To charge from 20 to 80 per cent will take around 20 minutes using the dedicated unit.

The unit is designed to withstand a 70G impact. So in case of an accident, it will be very important for marshals, officials, and spectators to take the appropriate steps for a safe approach towards the car, especially as the drivers will be wearing protective gear to avoid a situation of complete electricity currency inside the HV.

The 100kW electric motor of 134bhp will increase the power of the 2022 R1 to 514bhp, higher than many of the famed Group ‘B’ cars, therefore the aggressive aesthetic of the current WRC cars will be carried over to new generation vehicles which will not at all lose its appeal to fans.

Standardised crash structure

Road books will also be redefined to distinguish a normal car from the high-voltage HV such as the placing of “HY’ in red letters next to the front door panel and changing the background of the competition number to enable marshals, officials and spectators differentiate high-voltage vehicles from others.

For the design of the standardised crash structure, the manufacturers asked FIA to define a programme in close collaboration with them, in order to produce one safety package on behalf of all the teams.

This included doing just one set of crash tests, instead of multiple tests by each team.

The main targets for the improvement of the new structure design included the A-pillar (the pillars on both sides of the windscreen) and the side impacts.

Holmatro is already far ahead in the game of producing electric motor-driven extrication equipment of which Kenya is expected to purchase in order to standardise the Safari in the new WRC HV protocols.

“It is crucial that rescue teams have access to the latest rescue tools which meet the rigorous standards we set and to training programs that further enhance safety,” Harm Hermans, Holmatro’s CEO, said.

“Holmatro is proud to be chosen as an official supplier to the FIA and bring our rescue equipment to circuits worldwide."

“Holmatro hydraulic equipment and systems are used for rescue, industrial, and special tactics operations around the world.

“These types of applications demand reliable tools under all circumstances. To make sure that Holmatro users can fulfil their specialized tasks, we strive to be the best-in-class industry market leader by using game-changing technology.”

This will include a 3.9 kWh (750 volts) battery, an inverter/battery management system, together with the already known Motor Generation Unit (MGU) adding 134 hp (or 100 kW) to the car.

M-Sport did their tests in northern Spain (Bages) in late April, Hyundai in southern France, and Toyota in Viseu (Portugal) last May.