The 5 million seedlings farm I built

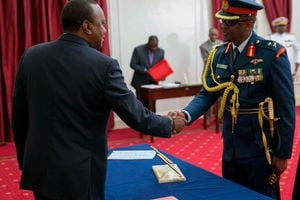

Steve Chege (left), the founder of Seed Delight Limited, with his workers inside a greenhouse on his farm in Lare, Nakuru County.

What you need to know:

- The seedlings propagation firm produces the plants for smallholder farmers in Nakuru, Laikipia, Baringo and Narok counties.

- The temperature and humidity in the germination chamber, which can hold 800,000 seedlings, are controlled to provide the ideal condition for the seeds.

- Another challenge is that most farmers depend on rain-fed agriculture, which is erratic making them not buy seedlings.

A six-kilometre road off the Njoro-Mau Narok highway at Gachuhi shopping centre leads one to Seeds Delight Ltd.

The seedlings propagation firm produces the plants for smallholder farmers in Nakuru, Laikipia, Baringo and Narok counties.

The eight-acre farm, located in Lare, Njoro sub-county, hosts thousands of seedlings flourishing inside massive greenhouses.

Tomato, spinach, cabbage, capsicum, onions, collard greens (sukuma wiki), managu and saget seedlings are among those grown.

The farm also propagates potato and avocado seedlings farmed in the open.

Steve Chege, the chief executive and founder of Seed Delight Ltd, says he started the farm in 2018 after resigning as a consultant at Centum, an investment firm, that year.

"Initially, I was a small-scale vegetable farmer doing it as a side hustle, but getting certified seedlings to plant was a big challenge. I would go for them from Naivasha and it was very costly. Each went for Sh4 or Sh5.”

Chege saw an opportunity in the seedlings business and seized it. “I started with one greenhouse that carried 160,000 seedlings. Then expanded the business by investing Sh5 million from my savings and soft loans from friends,” he tells Seeds of Gold.

“The money went on setting up seven more greenhouses and other infrastructure like water tanks, germination chambers and buying seeds among other overhead costs,” he adds.

Steve Chege the chief executive officer and founder of Seed Delight Limited, a seed propagation company based in Lare ward in Njoro sub-county, Nakuru County, showing mature vegetable seedlings in the greenhouse on May 20, 2022.

Chege explains that the process of growing the seedlings starts with mixing the main media, which comprises fine cocopeat from coconut fibres.

"We wash it in a trough for two days to remove dissolved salts since coconut grows in coastal areas where there is a lot of salinity," he says.

The mixture is turned into a lower electrical conductivity (EC) from a high of three to one before draining off the water.

"We measure the salt levels with an EC meter. With less salt, the seedlings will germinate properly." The mixture is then added vermiculate, fine ash from rocks from Uganda or the Eastern counties of Kitui, Machakos, and Makueni Ukambani.

“We get it from these areas because it has higher water retention. This is better than sand.”

The mixture is then put into plastic trays for planting seeds.

"Once the seeds are planted, you cover again with vermiculate and sprinkle some water and take them to the germination chamber," he says.

"Vermiculate helps in fast-germination and water-retention as cocopeat alone can allow water to pass through," explains Chege.

The temperature and humidity in the germination chamber, which can hold 800,000 seedlings, are controlled to provide the ideal condition for the seeds.

"Cabbages stay in the germination chamber for three days, tomatoes between five and six days and when they sprout we remove them."

The chamber is always closed as seedlings require darkness for faster growth. At its entrance, there is a disinfectant to ensure the tiny plants are not contaminated.

The seedlings are then taken to a nursery in a greenhouse and later transferred to the hardening area, a massive greenhouse which can host up to four million seeds, for two weeks.

Hardening area

"At the hardening area, we prepare the seedlings for outdoor conditions as the greenhouse has more air to mimic the field."

It takes about four weeks for the seedlings to be ready for sale. He sells a hardened tomato seedling for Sh3.50 while the raising fees for various vegetable seedlings are Sh1.50 to Sh1.70 depending on the number of days in the greenhouse.

Inside the greenhouses, blue and yellow sticky straps hang freely to control pests.

"The sticky straps help us to catch pests like thrips and white flies," says Chege, adding the company accepts certified seedlings from farmers for hardening at a fee.

The farm can trace each seed from the moment it comes from the farmers until it exits.

"We have tags in the trays denoting the seed variety, name of the client, a batch code, planting date and the number of trays.

This minimises any incidence of the mix-up and makes sure a farmer gets what he or she pays for seedlings."

At the fruit seedlings farm, he propagates Hass avocado variety, selling each for Sh200.

"We also train local farmers on the best practices during field days. Currently, we are not charging as we want to popularise the practices."

The farm, however, has to grapple with the challenges of the high cost of importing cocopeat from India, Srilanka and Estonia.

"We're are having challenges because of the high freight charges and exchange rates," says Chege.

Another challenge is that most farmers depend on rain-fed agriculture, which is erratic making them not buy seedlings.

Fertiliser costs

The high cost of fertiliser is another challenge the farm is grappling with. Chege, 46, who is a 2000 agribusiness management graduate from Egerton University, says he started with three employees but today has 11 on permanent terms and 20 casuals.

"We deal with over 3,000 smallholder farmers. We do five to six million seedlings in a month. It is a profitable venture," says Chege.

Peter Kamau, an agronomist in Nakuru, says for those doing heavy commercial seedling propagation, they must use hybrid seeds.

"High standards of hygiene must also be maintained to avoid passing pathogens when the crop is too tender," says Kamau.

He observes that disease management is key so that farmers buying seedlings can get maximum yields.

"Sanitisation at the entrance of greenhouses is a must. Seedlings are like babies, they need a lot of care to protect them from fungal infections and pests," says Kamau.